Understanding the Evolution of Cordless Angle Grinders

The development of the cordless angle grinder has reshaped construction tasks by eliminating reliance on fixed power sources. This equipment utilize advanced lithium-ion batteries to offer equivalent power output to traditional alternatives while enabling unlimited freedom. Professionals favor user-friendly designs with improved grip and vibration mitigation features, ensuring exactness during prolonged application. Moreover, developments in engine technology have substantially extended battery life, rendering them perfect for industrial applications.

Key Advantages of 20V Angle Grinder Systems

A 20v angle grinder achieves the perfect ratio between capability and convenience, establishing it as a preferred selection for both home users and contractors. The 20V system excels in providing steady rotational force for grinding hard materials like iron or stone. In contrast to lower-voltage models, 20V systems sustain maximum efficiency even under continuous stress, preventing overheating and power depletion. Several companies provide compatible batteries, allowing users to smoothly shift between equipment without downtime. This benefit improves productivity on busy job sites.

Identifying the Best Angle Grinder for Your Needs

Choosing the best angle grinder demands analyzing key factors such as blade diameter, engine capacity, and intended uses. For industrial operations, opt for models with higher amperage and durable construction to endure harsh application. On the other hand, compact options with modifiable safety shields suit detailed tasks like sculpting. Manufacturers often incorporate safety mechanisms such as anti-kickback and lock-off buttons to mitigate mishaps. Moreover, evaluate warranty terms and accessibility of replacement parts to ensure durable reliability.

Mastering the Angle Grinder Tool for Precision Work

An angle grinder tool serves as a multipurpose solution for slicing, polishing, and sharpening substances ranging from ceramic to metal rods. To achieve flawless results, workers must choose the correct attachment for each application—cutting discs for concrete or grinding wheels for metal. Correct approach entails keeping a firm grip and applying uniform force to minimize patchy surfaces. For intricate work, lowering the RPM and employing dedicated accessories improves precision. Frequent maintenance, including dust removal, prolongs the here equipment’s longevity.

Optimizing Performance with Variable Speed Angle Grinders

The variable speed angle grinder excels by providing customizable RPM controls, permitting users to tailor operation to specific surfaces and jobs. This capability prevents harm to delicate mediums like thin-gauge metal while optimizing productivity on dense substrates. For example, reducing the RPM when polishing plastic prevents deformation, whereas higher speeds accelerate shaping operations. High-end devices include electronic regulation systems that automatically modulate torque based on load, securing uniform performance.

Enhancing Safety Protocols for Angle Grinder Use

Although their functionality, angle grinders present considerable dangers if handled carelessly. Vital precautions include using protective gear such as eye protection, gauntlets, and flame-retardant attire. Consistently examine the tool for wear before operation, ensuring the guard is securely fixed and the disc is undamaged. Refrain from pushing the tool through substances, as this elevates the likelihood of kickback. When replacing discs, disconnect the power source to avoid accidental activation. Complying with these practices minimizes workplace injuries.

Future Innovations in Angle Grinder Technology

The evolution of angle grinders forecasts revolutionary improvements, including smart mechanisms that anticipate maintenance needs and optimize configurations for peak efficiency. Bluetooth networking may permit real-time performance tracking via digital platforms, enabling users to record usage patterns. Additionally, progress in power cell engineering may produce quick charging systems and higher capacity, enhancing operational time exponentially. Green designs and noise-reduction features are also anticipated to achieve adoption in answer to environmental regulations.

Conclusion: Investing in the Right Angle Grinder

Whether you are undertaking industrial projects or DIY tasks, investing in the right angle grinder necessitates thorough consideration of power, adaptability, and safety attributes. By prioritizing durable construction, user-friendly interfaces, and advanced technologies, users can realize superior outcomes while minimizing dangers. Stay knowledgeable about new innovations to utilize upgrades that complement their unique demands. Ultimately, a high-quality angle grinder functions as an essential asset in accomplishing expert outcomes.

Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Batista Then & Now!

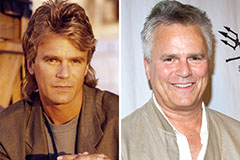

Batista Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!